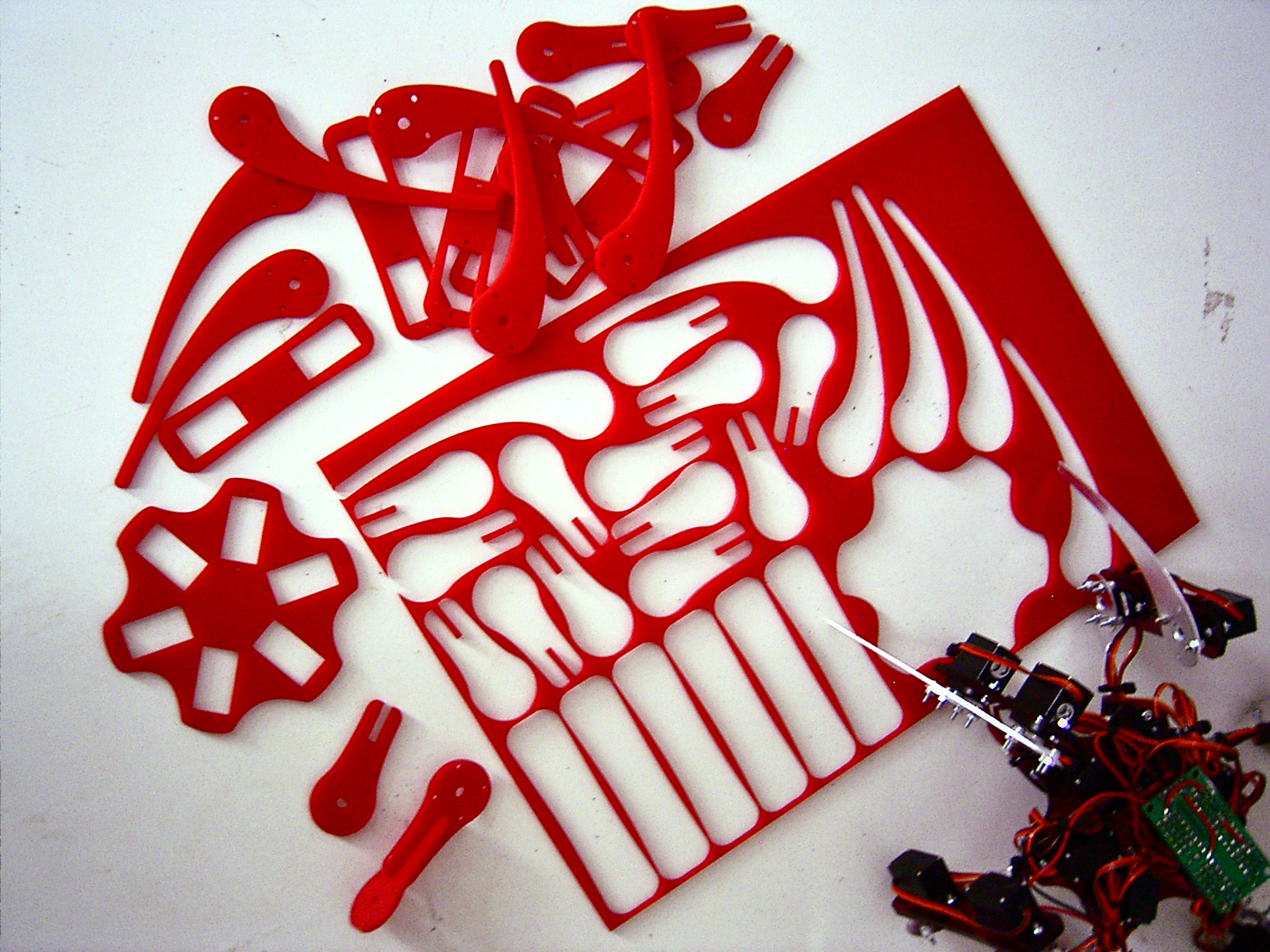

A4 design challenge

Build a cool reproducible robot out of one A4 size sheet of laser cut material

Objective

In many Fablabs Lasercutters are accesible to anyone with a good idea. This machine is perfect for cutting trough sheet material with high precision. Reason enough to use it for building cool robots! The contest is open for anyone willing to create a design and release it as Creative Commons…

Rules

Use one sheet of material, like 2 mm acrylic glass or 4 mm plywood. It is up to you, but use one single type of material. Keep the budget low, and keep external components and parts to a minimum, reproducibility of your design is key! You are allowed to use any type of controller (MBed, Arduino, NE555, whatever) – but again take note: reproducibility is key.

Criteria

+ many moving parts

+ many actuated parts

+ easy to reproduce

+ autononomy

+ interactive

+ cool design

———————-

– difficult parts

– high costs

– many motors or servo’s

– glue

– rest material

– complex tools

The more actuated and non-actuated degrees of freedom, the better. More activity with less motors is good. Your design should be easy reproducible and have a certain level of autonomy and interaction. Points will be subtracted for use of extra hardware, expensive parts, glue and complex tools. Also full use of your sheet is encouraged, so the amount of rest-material is taken into account.

Laser

Various laser cutters are at your disposal in your vicinity. Saxion students and members of the general public (i.e. everyone) can use the laser cutter at FablabEnschede during public opening hours. bring your design on USB stick, bring your own material and cut away… For UT students there is one option nearby in the SmartXP lab. There are fablabs to visit in every major city in the Netherlands. If you do not want to travel, you can send your design to A4laser.nl and have it cut and shipped back for you!

Submission

Make yourself known to us: join the facebook group or write an email. Submit your design before October 7th 2012. The prizewinner(s) will be selected shortly after that. Submission consists of one A4 PDF / SVG of the design, combined with picture or drawing, bill of materials and description of the end result. Submit to a4designchallenge@e13.nl

Prize

Beer or honor or both (or any beverage of choice accompanying said honor) – also some samples of a kit based on your design – produced by Studio13. We are currently working on more interesting stuff to lure more participants…

F.A.Q.

Why A4?: nice restriction, you can test your design using a normal printer and a piece of cardboard.

Which materials can I use? Most lasers will work with acrylic glass from 2-6 mm. Plywood from 2-5 mm. Metals cannot be cut. Also materials containing PVC cannot be cut due to safety reasons. Furthermore paper, leather, cardboard etc. can be used. Polycarbonate (Lexan) can be cut but gives charred edges.

Can I use scrap material? The problem with using scrap material is that when you use just this gear out of just this type of old DVD player that it is hard for somebody else to find exact that part and reproduce your work. Better to cut the gears from the A4-plate (which was the whole point)

Who owns my work? You do. You always hold the rights as author of your design work. We strongly suggest you to consider to distribute your design under Creative Commons license so it can be used for workshops, experiments and other non-profit causes.

Who will be the judge? to be decided. Peer review is a likely candidate 🙂

Which design tools can I use? Any tool will do. For cutting you need to supply the design as vector drawing (eps/eps works best). Suggested drawing tool if no other experience: Inkscape

Can I team up with others? Sure, but youʼll have to share the prize.

Write a Reply or Comment